Just imagine, a 50000 m2 construction site and you’re the project manager of a newly built hospital. Over 200 people are working on the site, and more new people are joining in. Each construction team is in charge of completely different tasks and knows how to perform it. One team finishes works, and the next one replaces them. As a manager, you know when the new materials will be delivered, you know the schedule of concreting, and you know exactly the schedule for the given week. All tasks are well-coordinated, and the process runs smoothly. How is it possible that so many people working in one place cooperate so well with each other?

The success to achieve such a state lies in a well-planned construction workflow. Without a proper plan, the construction site of such an investment would be one big communication and task chaos. The same is true with the implementation of BIM to the project.

The following article is included in the "How to become BIM Coordinator" In case it’s the first post you came across, I encourage you to read the introduction of the full series. I explain there how the articles have been organized to make sure you can get the most out of the series. Have a good read.

Table of Content

Although BIM technology brings freshness and innovation to the construction industry, it’s based on old and well-proven design methods. One of the main objectives of good design practices involves determining a clearly defined project goal and establishing a plan to achieve this goal. When implementing BIM such a plan is often referred to as the BIM Execution Plan or BEP for short.

DO YOU WANT TO BECOME A BIM COORDINATOR ? WE ARE BUILDING AN ONLINE PROGRAM TO BOOST YOUR CARRER IN BIM

What is BEP actually?

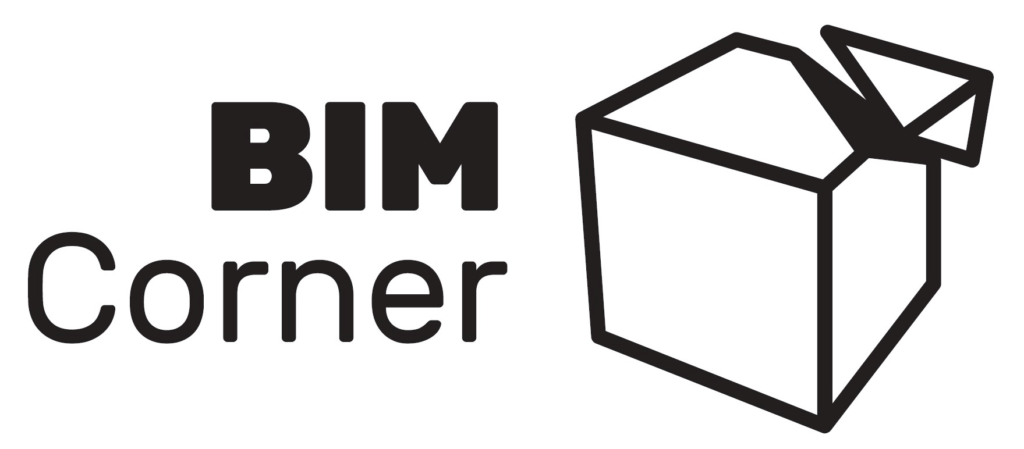

First, let’s explain what exactly BEP is and answer the question of why it’s so important for proper implementation of BIM methodology on a project or in a company.

BEP is a plan defining the goals of implementing BIM technology in a project. It describes how the constructed model will be applied, explains the implementation processes and the ways of information exchange. It also contains information on the entire project infrastructure required for a successful BIM implementation, i.e.: the technologies we will apply, the team responsible for the implementation and the contracts to be fulfilled. In short, BIM Execution Plan focuses on delivering value by implementing BIM to the project.

Referring to the British standards, we may also mention the fact that the BEP itself may be prepared as a direct response to the ordering party’s requirements concerning the information contained in the model. The requirements are written in a document called EIR (Employer Information Requirement).

You have to remember there is no universal BIM implementation method for every project. Each team should effectively design a well-adapted BEP implementation strategy. Therefore, only the team understanding the project’s goals, its characteristics, and the capabilities of its members can effectively implement BIM in the project. After establishing the plan, the team should follow and monitor progress according to the plan. Constant developing, updating, and correcting the plan at every stage of the project is essential to get the maximum benefit from BIM implementation.

Why do we need BEP?

I guess we have already answered this question in the previous paragraph, but let’s have a closer look at the areas where BEP can be particularly helpful in implementing BIM.

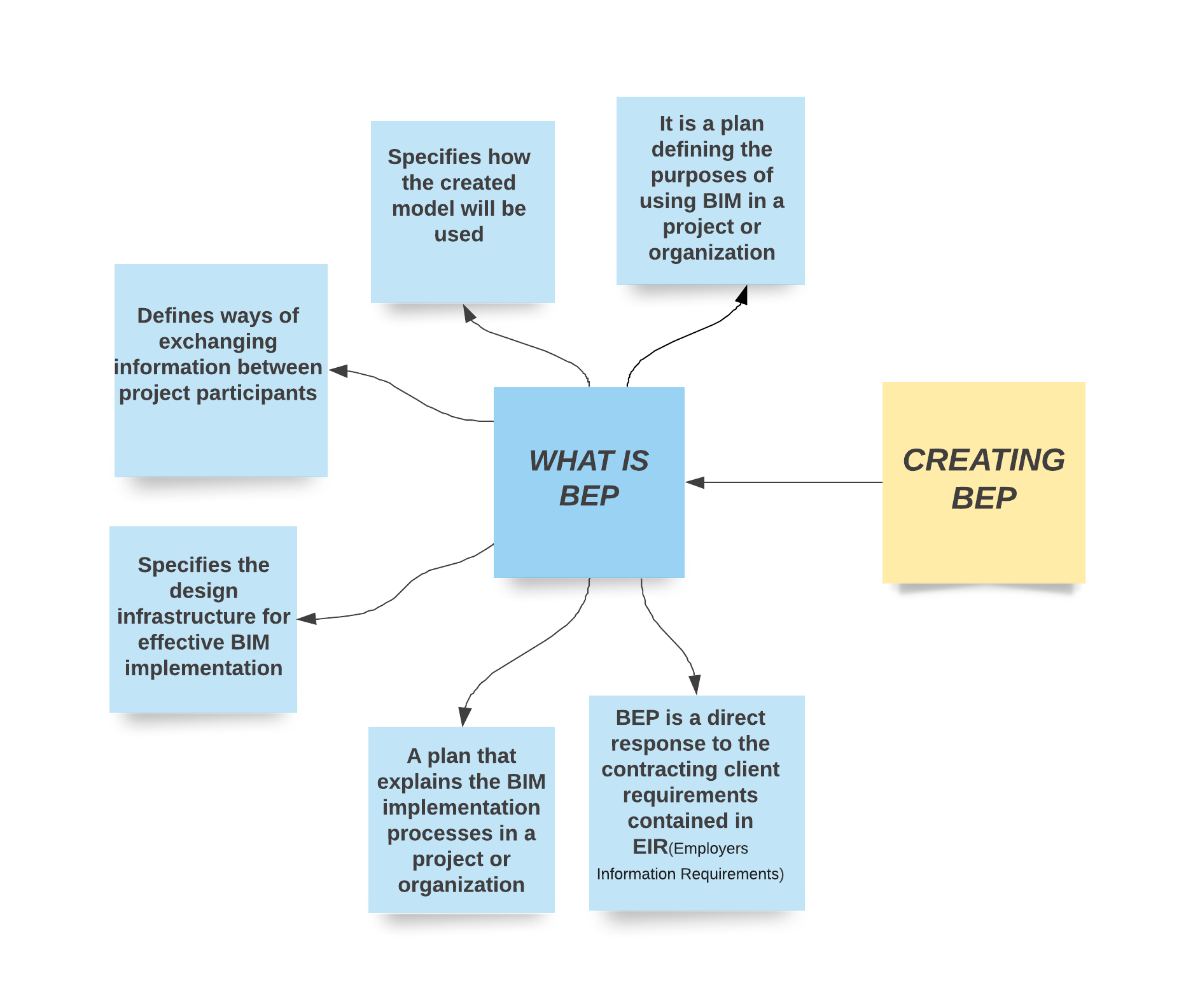

One of the main benefits we can mention here is as follows:

- The organization or project receives a much better understanding of the roles and responsibilities of the individual people in the project team.

- The specific goals for the BIM implementation or organization are clarified, thus enabling the achievement of such goals.

- Knowing the ambitions of the project and team capabilities, it’s possible to design an implementation process tailored to the characteristics of the project and the team’s workflow.

- BEP will be a guide for new project participants. By describing the routines, processes, and strategies, it’s much easier to implement new employees in the project team.

- Due to the BEP, from the very beginning of the implementation, we have a good view of the team’s knowledge and skills. Thus, it provides us with an excellent foundation for planning training courses to upgrade competences or employing appropriate specialists.

- Knowing the project goal, personnel skills, and technological infrastructure, it’s much easier for us to assess which hardware or software to purchase for the implementation.

The abovementioned points represent merely a few fundamental benefits of developing an effective BIM implementation plan. Ultimately, the whole team responsible for the BIM implementation benefits from it. By increasing the level of planning, the number of uncertainties in the implementation process is reduced thereby also reducing the overall risk for all parties involved in the project.

The series structure

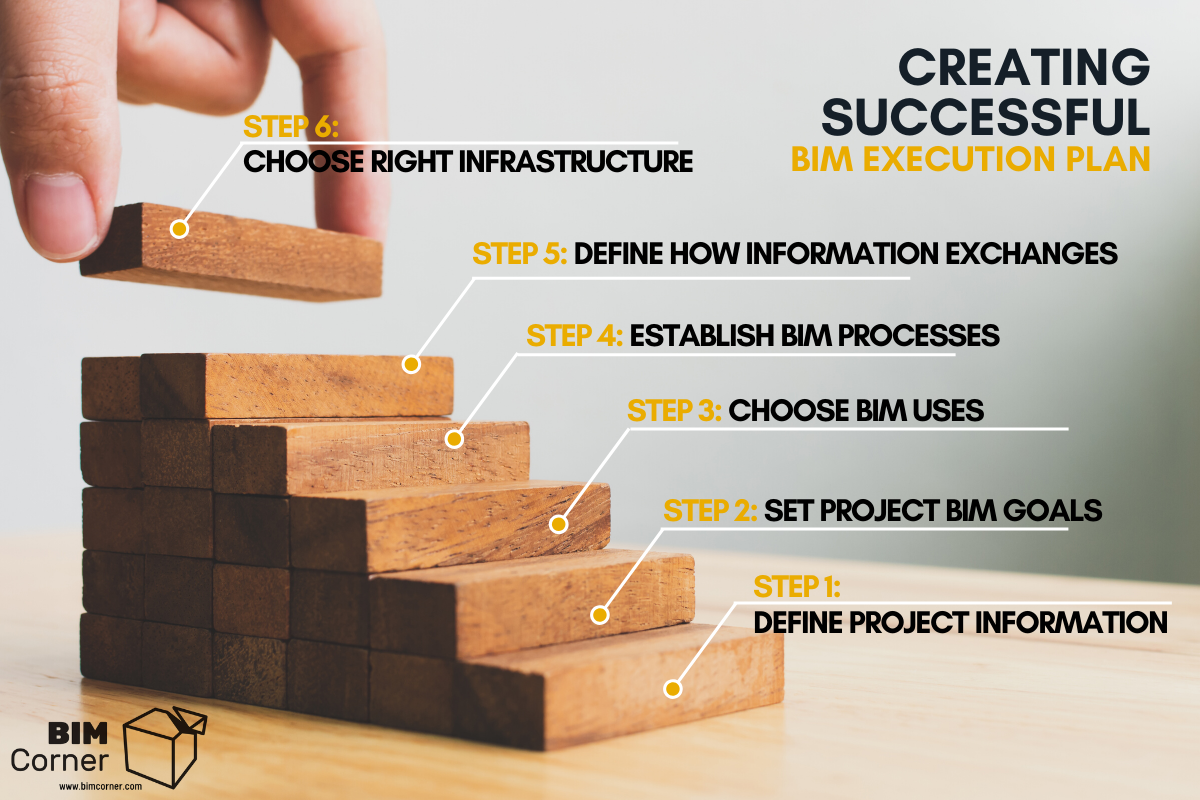

Once we know what BEP is all about and how important role it plays in the process of BIM implementation in a project/organization, then let’s go to the point and start writing it. I divided the process of developing the document into five steps. They will be described in detail in separate articles. Here we will deal with the first two. Below is a list of the steps we will deal with in detail.

Steps to establish an effective BIM Execution Plan:

Creating BIM Execution Plan

Typically, big companies start creating a BEP using a company template for such a document. It fills in the information according to the requirements for the project. For the requirements of this series, I created a BEP template, which will serve us while filling in the next sections of the plan.

Keep in mind that every BEP is unique. Some may contain multiple pages and be divided into multiple sections, while others may be three or four pages long. It all depends on the level of detail, the complexity of the project, its characteristics, requirements, and local regulations. However, the length of the document itself is not so important. The key is to ensure that the plan effectively guides all team members towards the intended goals of BIM implementation.

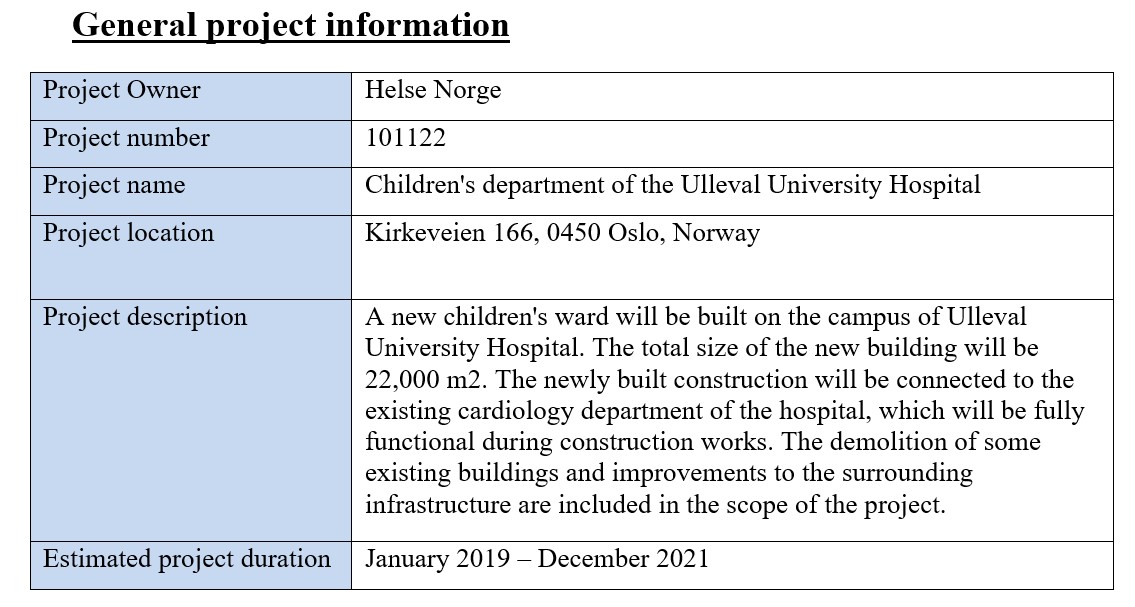

Step 1 - Defining basic information concerning the project

When creating a BIM Execution Plan, first of all, we have to provide basic information concerning the project. It will provide everyone who doesn’t know the project yet, with a general view of the project scope. For this guide, we will create the BEP of the newly establishe ward building of the University Hospital in Oslo.

Normally in this section, we provide data such as:

Project number – individual project number, simplifies the identification of project documents of a particular project. Particularly useful if there are many projects carried out simultaneously or if we carry out many projects for the same client.

Project name – a name established by the client or project team, used by all involved persons when discussing the project.

Project owner – here we provide information on who is the project owner. It can be the name of the person or the name of the company/institution where this person works.

Project localization – in case of the localization, we should specify either the coordinates of the project or the actual address of the investment.

Project description – the description provides a more detailed picture of what we intend to build. The person reading the BEP receives an additional quick portion of specific facts concerning the project.

Project duration – information concerning the duration of the project is provided here.

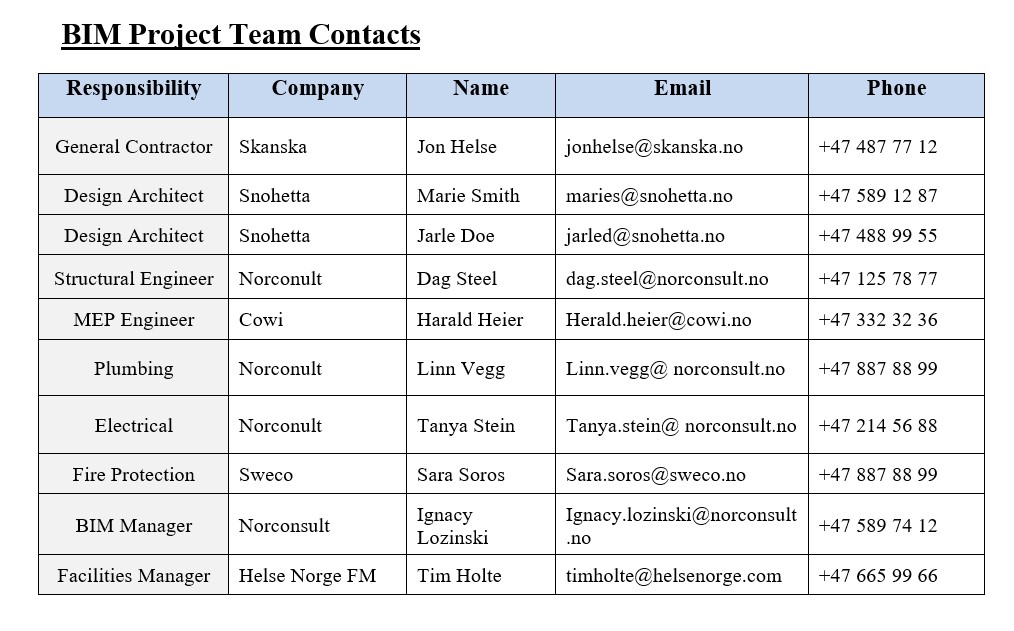

Identify key team members and model managers

A further elementary section that an effective BEP should contain includes the contact details and names of the persons responsible for the BIM implementation in each project part. In our template, we will find such information as:

- Position/role of the person on the project

- What company/organization does the person work for

- Name and last name

- Contact details: e-mail address, phone number

This point is significant since we all work as a group. We need to know exactly how we can contact other people in the team. If there are any questions related to the project as it progresses, a team member can look at the chart and find the necessary contact, all in one place. It’ s essential that the chart is updated as the project progresses.

Define project milestones

Although project milestones may evolve during the project, however, it’s important to include such information in the BEP. Thanks to this information, it helps industry teams to establish their work plans to meet the overall project schedule. This section may contain more or less detailed information, depending on the size and scope of the project.

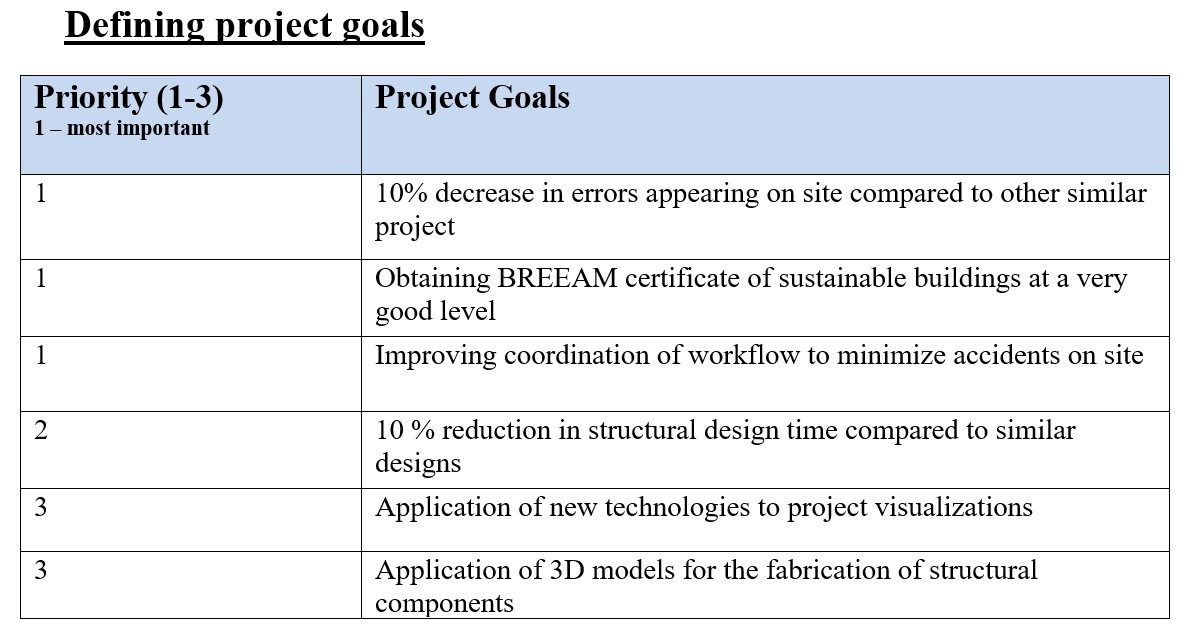

Step 2 - Defining project goals

Once we have filled our BEP with basic information concerning the project, then it’s time to skip to the next section.

The second step to creating an effective BIM Execution Plan is to consider the benefits that BIM may bring to our project, and on that basis define goals we intend to achieve. To effectively define the goals, it’s worth remembering that such goals should be related to the created project, be measurable, and achievable for the project team.

All right, but what goals are we talking about in general? BEP goals may vary and depend on the project characteristics.

- If for instance, we aim to increase the team competences when working with BIM and consider the project as a pilot project then your goals may include:

- Increase of the knowledge of 3D design programs among the project team,

- Having the inter-industry coordination experience,

- Increase of the effectiveness of designers’ work through more efficient use of design tools,

- Establishment of the routines to automate repetitive design tasks.

- A frequent ambition of the BIM implementation team is to increase the efficiency and safety of the project. This general statement may cover:

- Reducing the time to create project documentation through efficient coordination of 3D models,

- Efficient work of the teams on site due to the use of 3D models and constantly updated documentation,

- Automating repetitive design tasks,

- More efficient work on the construction site due to pre-developed simulations of construction work,

- Increased safety on the construction site through faster detection of potential risks through 3D models and simulations.

- BIM, alongside increasing the project’s efficiency, often contributes to improving the quality of the project itself, and goals in this category may be:

- Creating more accurate design documentation for more effective implementation in subsequent phases,

- Developing a more energy-efficient design by iterating energy consumption models faster,

- Enhancing the quality of designed solutions through detailed coordination of 3D systems with architectural and structural elements,

- Improving control over the project budget by implementing the information on the prices of installed solutions.

- BIM technology is increasingly becoming available in new fields of action. Companies are exploring the potential of BIM technology and looking for other methods of applying 3D models and the information they contain. Searching for new areas of BIM application may be a goal for companies with a stable BIM strategy to increase their “range” of services proposed to customers.

- Application of game technology to create an interactive environment for the construction site,

- Application of AR or VR technology for investment promotion purposes,

- The use of information in the model for solutions applying artificial intelligence to optimize construction processes.

The abovementioned goals are merely suggestions to inspire. Remember the right goals will encourage the team to implement BIM, not the other way around.

When setting goals, adding priorities seems to be good practice. Prioritizing a goal gives you a better understanding of what the project group is focusing on and which goals are secondary. In our example of a hospital ward project, we can use the following goals:

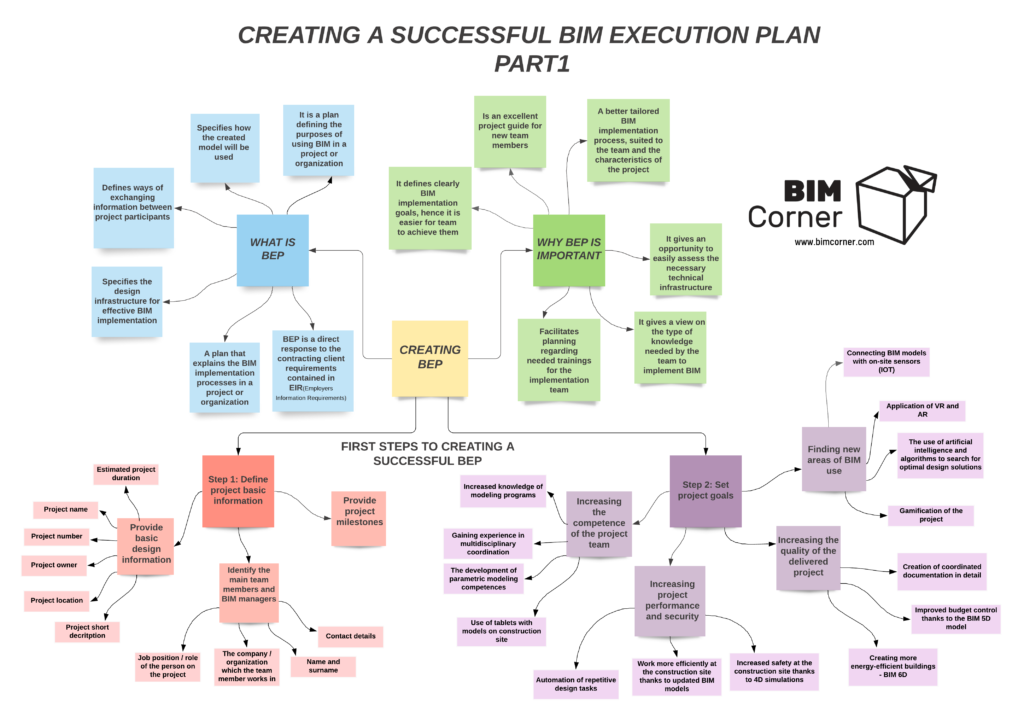

Mind map for part 1 of the guide

To better systematize the knowledge from today’s article, I have created a mind map that visually illustrates topics covered in this first part of the guide:

Summary

BIM technology implementation requires detailed planning and modification of standard design processes. It’s not only a shift in the workflow but also in the way of thinking. Without a proper guide, it would be difficult for us to adjust to these modifications and implement them. Here BEP technology comes to our aid.

Although in today’s article we only addressed the initial issue of the whole plan, yet it’s an essential step. Without well-defined and measurable goals, we won’t get far and we’ll get lost at the first possible occasion (and there will be many, please, believe me).

Thank you for keeping up to the very end, and reading those words. I know it’s not an easy reading, but I’m sure you will benefit from creating a BEP in your company. I’m also curious how the process of creating BEP in your company/organization looks like? Do you already have experience in creating it or maybe you are just beginning? Leave a comment below or share it with your industry colleagues. See you in the next article in the series.

The information contained in the guide is based on my own experience but also inspired by Penn State University’s work in the BEP development:

https://www.bim.psu.edu/

as well as ISO 19650-1 and 19650-2 standards:

https://www.bsigroup.com/en-GB/iso-19650-BIM/

Check out other articles from about Creating Successful BEP:

The simplicity of this complex knowledge delivery makes this article easy to read. The essence of the content you put on images- priceless. Thank you!